Every company or every business HAVE Supply Chain. Even a small grocery store have Supply Chain. But they just do not realize it. No matter the business is about selling products or services, they still need to find their supplier, select the best one AFTER they Successfully specify their requirements and planning supply.

Ally Conrad, an Event Manager have listed 5 Steps to be successful in selecting supplier. Let see what she had in her mind shall we?

1) Supplier Selection Scorecard

- The supplier selection scorecard contains all the important elements you require in a supplier. It has long been stated, “That which does not get measured, does not get done”.

Learn this to match with Malaysian culture in our upcoming course:

Specifying Requirements & Planning Supply

2-3 Aug 2017

2) Identify Suitable Supplier

- Create the pool from which you will select a supplier. During this part of the process you will want to consider:

Current suppliers – Starting with suppliers you have experience with and established relationships is generally a good idea.

Past suppliers – Depending upon the reasons why they are ‘past’ and not ‘current.’

Competitors – You may be in a position to buy from a competitor if it is ethical and low-risk.

Industry groups – many of which are non-profit and maintain data bases of member companies.

Recommendations and prior business relationships – perhaps created while working at other companies.

Internet – which offers myriad opportunities to find, research, and contact potential suppliers.

Learn this intensely in our course:

Appraising & Short- Listing Suppliers

30 Sept- 1 Oct 2017

3) Scorecard Ranking

Tabulate the information you collect and use the scorecard to rank the potential suppliers.

Depending upon the complexity and/or criticality of the product or service, you may:

Select the highest ranking supplier – Recognize that while you are not required to pick the top scorer, moving too far down the list is a red flag, indicating the process was flawed.

Choose more than one for further qualification – May include interviews, site visits, etc.

Take away the knowledge in our upcoming course:

Obtaining & Selecting Offers

21- 22 Oct 2017

4) Negotiate

After you have narrowed the list to a manageable number of best options, possibly even one, let the negotiations begin!

Depending on the critical good or service, you may negotiate with just the top supplier on your scorecard, even if others remain on the list of potentials.Sure, to negotiate is not easy.

Learn the art of negotiating offers in our course:

Negotiating Offers

28-29 Oct 2017

5) Create Contract and Activate Purchasing System

Once an agreement has been reached, a contract is signed. Again, depending upon complexity, lawyers may be involved. For simpler transactions, the Purchase Order is the contract.

How to lower the cost while purchasing? Get it right in:

Group Purchasing Course

9-10 Sept 2017

The last step is to activate your procurement system.

Are you on the right track for procurement? Get to know in:

Environmental Procurement

12-13 Aug 2017

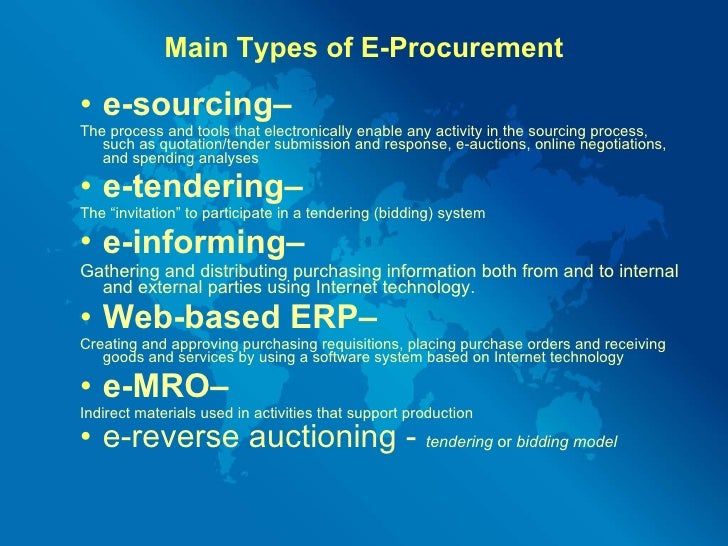

E-Procurement

7-8 Oct 2017

Articles extracted from Ally Conrad

========================================================================